What is a electroplating

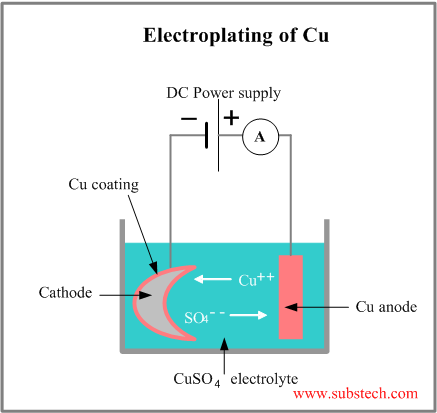

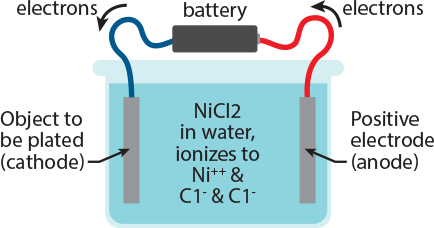

What Is A Electroplating. Electroplating is the application of electrolytic cells in which a thin layer of metal is deposited onto an electrically conductive surface. Electroplating is a popular metal finishing and improving process used in a wide range of industries for various applications. Electroplating is the process of coating a metal with a thin layer of another metal by electrolysis to improve the metal s corrosion resistance. The electrodes and electrolyte are made from carefully chosen elements or compounds.

Electroplating Explained Cdr Samfa Home Page From yumpu.com

Electroplating Explained Cdr Samfa Home Page From yumpu.com

Despite the popularity of electroplating however very few outside of the industry are familiar with the process what it is and how it works. A cell consists of two electrodes conductors usually made of metal which are held apart from one another. Electroplating is basically the process of plating a metal onto the other by hydrolysis mostly to prevent corrosion of metal or for decorative purposes. Electroplating is a popular metal finishing and improving process used in a wide range of industries for various applications. Electroplating is also known as electrodeposition and electroplated coating. Electroplating is also known as electro deposition and it is used to produce a metallic coating on the surface of an object using electric current.

The electrodes and electrolyte are made from carefully chosen elements or compounds.

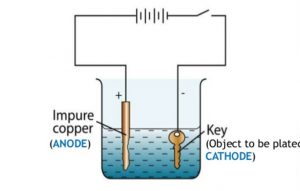

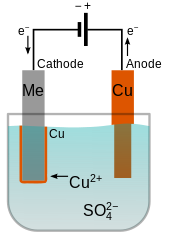

The electrodes and electrolyte are made from carefully chosen elements or compounds. The electrodes are immersed in an electrolyte a solution. Electroplating is widely used in indus. Electroplating is a popular metal finishing and improving process used in a wide range of industries for various applications. The electrolyte is a solution of a salt of the metal to be coated. The part to be coated acts as the cathode of an electrolytic cell.

Source: selectiveplatinginc.com

Source: selectiveplatinginc.com

Electroplating is also known as electrodeposition and electroplated coating. Electroplating is widely used in indus. And the anode is usually either a block of that metal or of some inert conductive material. Electroplating involves passing an electric current through a solution called an electrolyte. The electrolyte is a solution of a salt of the metal to be coated.

Source: substech.com

Source: substech.com

The metals most commonly used in plating are. Electroplating is also known as electrodeposition and electroplated coating. This is done by dipping two terminals called electrodes into the electrolyte and connecting them into a circuit with a battery or other power supply. Electroplating is basically the process of plating a metal onto the other by hydrolysis mostly to prevent corrosion of metal or for decorative purposes. The process of electroplating requires a negative charge to be added to the object being electroplated.

Source: marshplating.com

Source: marshplating.com

The electrodes and electrolyte are made from carefully chosen elements or compounds. Electroplating is a general name for processes that create a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. This is done by dipping two terminals called electrodes into the electrolyte and connecting them into a circuit with a battery or other power supply. A cell consists of two electrodes conductors usually made of metal which are held apart from one another. Electroplating involves passing an electric current through a solution called an electrolyte.

Source: m.youtube.com

Source: m.youtube.com

The metals most commonly used in plating are. It s typically used to prevent corrosion and extend the life of the metal. Electroplating is the process of plating one metal onto another by hydrolysis most commonly for decorative purposes or to prevent corrosion of a metal. There are also specific types of electroplating chemistry libretexts. The electrodes are immersed in an electrolyte a solution.

Source: britannica.com

Source: britannica.com

Electroplating is widely used in indus. There are also specific types of electroplating chemistry libretexts. And the anode is usually either a block of that metal or of some inert conductive material. A cell consists of two electrodes conductors usually made of metal which are held apart from one another. The electrolyte is a solution of a salt of the metal to be coated.

Source: en.wikipedia.org

Source: en.wikipedia.org

Electroplating is also known as electro deposition and it is used to produce a metallic coating on the surface of an object using electric current. There are also specific types of electroplating chemistry libretexts. It s typically used to prevent corrosion and extend the life of the metal. The electrolyte is a solution of a salt of the metal to be coated. The process of electroplating requires a negative charge to be added to the object being electroplated.

Source: quora.com

Source: quora.com

A cell consists of two electrodes conductors usually made of metal which are held apart from one another. This object is subsequently immersed in an ionic solution carrying positive charge. The process of electroplating requires a negative charge to be added to the object being electroplated. Electroplating is the process of coating a metal with a thin layer of another metal by electrolysis to improve the metal s corrosion resistance. Electroplating refers to a process that adds a surface layer of metal to another.

Source: classnotes.org.in

Source: classnotes.org.in

The current is provided by an external power supply. The electrolyte is a solution of a salt of the metal to be coated. Electroplating refers to a process that adds a surface layer of metal to another. Electroplating is also known as electrodeposition and electroplated coating. Electroplating is the process of coating a metal with a thin layer of another metal by electrolysis to improve the metal s corrosion resistance.

Source: yumpu.com

Source: yumpu.com

The electrolyte is a solution of a salt of the metal to be coated. The part to be coated acts as the cathode of an electrolytic cell. The process uses an electric current to reduce dissolved metal cations to develop a lean coherent metal coating on the electrode. A cell consists of two electrodes conductors usually made of metal which are held apart from one another. This is done by dipping two terminals called electrodes into the electrolyte and connecting them into a circuit with a battery or other power supply.

Source: explainthatstuff.com

Source: explainthatstuff.com

The electrolyte is a solution of a salt of the metal to be coated. The electrolyte is a solution of a salt of the metal to be coated. Electroplating is the process of plating one metal onto another by hydrolysis most commonly for decorative purposes or to prevent corrosion of a metal. The metals most commonly used in plating are. Electroplating is also known as electro deposition and it is used to produce a metallic coating on the surface of an object using electric current.

Source: thoughtco.com

Source: thoughtco.com

Electroplating is a popular metal finishing and improving process used in a wide range of industries for various applications. There are also specific types of electroplating chemistry libretexts. Despite the popularity of electroplating however very few outside of the industry are familiar with the process what it is and how it works. Electroplating is basically the process of plating a metal onto the other by hydrolysis mostly to prevent corrosion of metal or for decorative purposes. Electroplating is the process of plating one metal onto another by hydrolysis most commonly for decorative purposes or to prevent corrosion of a metal.

Source: toppr.com

Source: toppr.com

The electrodes and electrolyte are made from carefully chosen elements or compounds. The process uses an electric current to reduce dissolved metal cations to develop a lean coherent metal coating on the electrode. The electrodes and electrolyte are made from carefully chosen elements or compounds. Despite the popularity of electroplating however very few outside of the industry are familiar with the process what it is and how it works. The part to be coated acts as the cathode of an electrolytic cell.

Source: sharrettsplating.com

Source: sharrettsplating.com

This is done by dipping two terminals called electrodes into the electrolyte and connecting them into a circuit with a battery or other power supply. Electroplating is a general name for processes that create a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The process uses an electric current to reduce dissolved metal cations to develop a lean coherent metal coating on the electrode. The part to be coated acts as the cathode of an electrolytic cell. This is done by dipping two terminals called electrodes into the electrolyte and connecting them into a circuit with a battery or other power supply.

Source: byjus.com

Source: byjus.com

Electroplating is also known as electrodeposition and electroplated coating. Electroplating is also known as electrodeposition and electroplated coating. This is done by dipping two terminals called electrodes into the electrolyte and connecting them into a circuit with a battery or other power supply. The process uses an electric current to reduce dissolved metal cations to develop a lean coherent metal coating on the electrode. The electrodes are immersed in an electrolyte a solution.

Source: en.wikipedia.org

Source: en.wikipedia.org

Electroplating involves passing an electric current through a solution called an electrolyte. The process uses an electric current to reduce dissolved metal cations to develop a lean coherent metal coating on the electrode. Electroplating is the process of coating a metal with a thin layer of another metal by electrolysis to improve the metal s corrosion resistance. Electroplating is the application of electrolytic cells in which a thin layer of metal is deposited onto an electrically conductive surface. It s typically used to prevent corrosion and extend the life of the metal.

If you find this site beneficial, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title what is a electroplating by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.