Silver plating on copper process

Silver Plating On Copper Process. The benefits of silver plating. In the work by formanek et al. I think that you will need a silver strike and probably a nickel strike. I remember doing this way back in high school and it was a simple process of introducing battery current to a tank of chemicals.

Electroplating Britannica From britannica.com

Electroplating Britannica From britannica.com

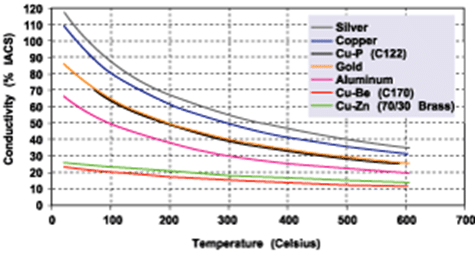

Silver copper composite powders were prepared by electroless plating method in aqueous system at room temperature. Nh4oh nh4 2so4molar ratio activation time and feeding rate of silver ion solution. When the process is performed over nickel silver the result is usually called electroplated nickel silver. The dense and uniform silver coating layer was obtained by strictly controlling the activation and deposition process variables such as. Its silver equivalent amalgam silvering was executed in the same manner by applying a paste of silver amalgam and mercury to a copper alloy object and subsequent heating to form a diffusion. 5 the silver plating occurs via an electroless plating process which coats only the structure that was produced and not the substrate onto which the structure was fabricated.

Its silver equivalent amalgam silvering was executed in the same manner by applying a paste of silver amalgam and mercury to a copper alloy object and subsequent heating to form a diffusion.

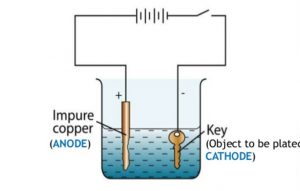

Silver is applied on to the preliminary coatings of nickel and copper though there might be certain variations. Nh4oh nh4 2so4molar ratio activation time and feeding rate of silver ion solution. Due to the strength of silver this type of coating offers excellent corrosion resistance to the base material and the product as a whole. Silver plating is an electrolytic process. Their web site says that their 50 50 solution will plate directly to copper. I remember doing this way back in high school and it was a simple process of introducing battery current to a tank of chemicals.

Source: advancedplatingtech.com

Source: advancedplatingtech.com

Due to the strength of silver this type of coating offers excellent corrosion resistance to the base material and the product as a whole. Silver copper composite powders were prepared by electroless plating method in aqueous system at room temperature. 5 the silver plating occurs via an electroless plating process which coats only the structure that was produced and not the substrate onto which the structure was fabricated. The dense and uniform silver coating layer was obtained by strictly controlling the activation and deposition process variables such as. Besides nickel silver the process is commonly used on copper steel titanium graphite ceramic plastic and aluminum.

Source: explainthatstuff.com

Source: explainthatstuff.com

What is the detailed process for electroplating silver onto copper 2001. Nh4oh nh4 2so4molar ratio activation time and feeding rate of silver ion solution. Its silver equivalent amalgam silvering was executed in the same manner by applying a paste of silver amalgam and mercury to a copper alloy object and subsequent heating to form a diffusion. The benefits of silver plating. Silver plating of copper or copper alloys silver properties silver plating of copper or copper alloys is a highly functional finish for transferring heat and electricity utilized across a wide breath of industries.

Source: kernowcraft.com

Source: kernowcraft.com

When you talk to them get a complete process for plating silver on copper. Their web site says that their 50 50 solution will plate directly to copper. I think that you will need a silver strike and probably a nickel strike. Besides nickel silver the process is commonly used on copper steel titanium graphite ceramic plastic and aluminum. What is the detailed process for electroplating silver onto copper 2001.

Source: electroplating-process.blogspot.com

Silver plating of copper or copper alloys silver properties silver plating of copper or copper alloys is a highly functional finish for transferring heat and electricity utilized across a wide breath of industries. Silver plating of copper or copper alloys silver properties silver plating of copper or copper alloys is a highly functional finish for transferring heat and electricity utilized across a wide breath of industries. I am not aware of any non cyanide silver strikes. Silver has been applied since late 1800s onelectrical switchgear and other components that pass electrical current. I think that you will need a silver strike and probably a nickel strike.

Source: intatech.com

Source: intatech.com

One can make use of its properties either for functional purposes including increased electronic performance or for certain decorative purposes. Their web site says that their 50 50 solution will plate directly to copper. What is the detailed process for electroplating silver onto copper 2001. The benefits of silver plating. Due to the strength of silver this type of coating offers excellent corrosion resistance to the base material and the product as a whole.

Source: britannica.com

Source: britannica.com

I remember doing this way back in high school and it was a simple process of introducing battery current to a tank of chemicals. What is the detailed process for electroplating silver onto copper 2001. Silver has been applied since late 1800s onelectrical switchgear and other components that pass electrical current. I am not aware of any non cyanide silver strikes. When the process is performed over nickel silver the result is usually called electroplated nickel silver.

Source: youtube.com

Source: youtube.com

In order to accomplish this the group produced a chemically modified polymer resin a commercially available acrylate monomer with some amount of styrene added. Silver plating provides several benefits. Its silver equivalent amalgam silvering was executed in the same manner by applying a paste of silver amalgam and mercury to a copper alloy object and subsequent heating to form a diffusion. 5 the silver plating occurs via an electroless plating process which coats only the structure that was produced and not the substrate onto which the structure was fabricated. Silver copper composite powders were prepared by electroless plating method in aqueous system at room temperature.

Source: classnotes.org.in

Source: classnotes.org.in

In order to accomplish this the group produced a chemically modified polymer resin a commercially available acrylate monomer with some amount of styrene added. They may have work around methods. When the process is performed over nickel silver the result is usually called electroplated nickel silver. Nh4oh nh4 2so4molar ratio activation time and feeding rate of silver ion solution. Due to the strength of silver this type of coating offers excellent corrosion resistance to the base material and the product as a whole.

Source: goldn.co.uk

Source: goldn.co.uk

Due to the strength of silver this type of coating offers excellent corrosion resistance to the base material and the product as a whole. Silver is applied on to the preliminary coatings of nickel and copper though there might be certain variations. I think that you will need a silver strike and probably a nickel strike. I want to electroplate silver onto copper to fix old silver plate items that i have that are worn in places. Nh4oh nh4 2so4molar ratio activation time and feeding rate of silver ion solution.

Source: advancedplatingtech.com

Source: advancedplatingtech.com

Its silver equivalent amalgam silvering was executed in the same manner by applying a paste of silver amalgam and mercury to a copper alloy object and subsequent heating to form a diffusion. In order to accomplish this the group produced a chemically modified polymer resin a commercially available acrylate monomer with some amount of styrene added. One can make use of its properties either for functional purposes including increased electronic performance or for certain decorative purposes. What is the detailed process for electroplating silver onto copper 2001. Silver copper composite powders were prepared by electroless plating method in aqueous system at room temperature.

Source: pcbway.com

Source: pcbway.com

I am not aware of any non cyanide silver strikes. Their web site says that their 50 50 solution will plate directly to copper. I want to electroplate silver onto copper to fix old silver plate items that i have that are worn in places. Silver copper composite powders were prepared by electroless plating method in aqueous system at room temperature. One can make use of its properties either for functional purposes including increased electronic performance or for certain decorative purposes.

Source: studyrankersonline.com

Source: studyrankersonline.com

When the process is performed over nickel silver the result is usually called electroplated nickel silver. I want to electroplate silver onto copper to fix old silver plate items that i have that are worn in places. When the process is performed over nickel silver the result is usually called electroplated nickel silver. I think that you will need a silver strike and probably a nickel strike. Silver plating provides several benefits.

Source: goldn.co.uk

Source: goldn.co.uk

Besides nickel silver the process is commonly used on copper steel titanium graphite ceramic plastic and aluminum. The benefits of silver plating. I am not aware of any non cyanide silver strikes. I remember doing this way back in high school and it was a simple process of introducing battery current to a tank of chemicals. They may have work around methods.

Source: hackaday.com

Source: hackaday.com

In order to accomplish this the group produced a chemically modified polymer resin a commercially available acrylate monomer with some amount of styrene added. Their web site says that their 50 50 solution will plate directly to copper. In the work by formanek et al. What is the detailed process for electroplating silver onto copper 2001. Its silver equivalent amalgam silvering was executed in the same manner by applying a paste of silver amalgam and mercury to a copper alloy object and subsequent heating to form a diffusion.

Source: greenelyon.com

Source: greenelyon.com

The benefits of silver plating. I want to electroplate silver onto copper to fix old silver plate items that i have that are worn in places. Silver plating is an electrolytic process. When you talk to them get a complete process for plating silver on copper. One can make use of its properties either for functional purposes including increased electronic performance or for certain decorative purposes.

If you find this site helpful, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title silver plating on copper process by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.