Refining iron ore

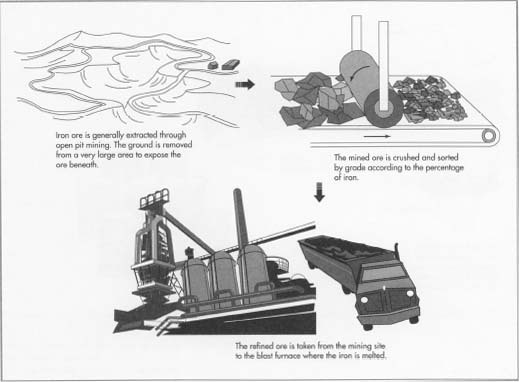

Refining Iron Ore. About to refine lots of iron ore. To create pure iron one must deoxygenate the ore leaving only iron atoms behind which is the essence of the refining process. Refining 2 the mined ore is crushed and sorted. The iron is usually found in the form of magnetite fe 3 o 4 72 4 fe hematite fe 2 o 3 69 9 fe goethite feo oh 62 9 fe.

Extracting Ores Mining Of Mineral Resources Siyavula From intl.siyavula.com

Extracting Ores Mining Of Mineral Resources Siyavula From intl.siyavula.com

The ores are usually rich in iron oxides and vary in color from dark grey bright yellow or deep purple to rusty red. Item script dropped by. Iron ores are rocks and minerals from which metallic iron can be economically extracted. The best grades of ore contain over 60 iron. Steelmaking is the second step in producing steel from iron ore. Blacksmiths can refine iron ore into iron iron and coal into steel and elemental ores into elemental stones.

It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material whereas in refining the final material is usually identical chemically to the original one only it is purer.

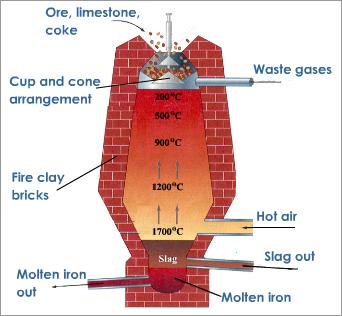

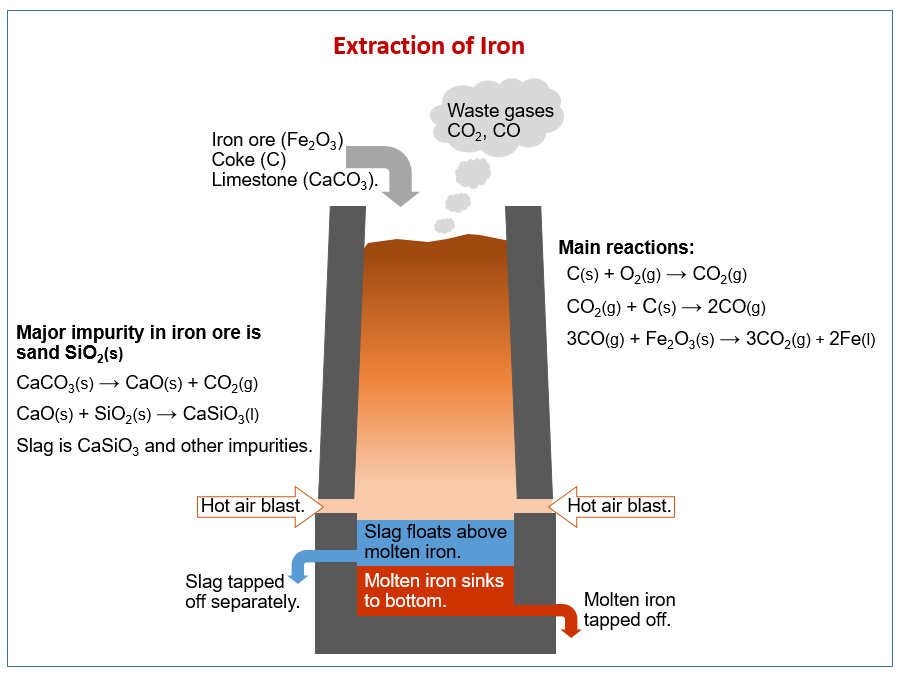

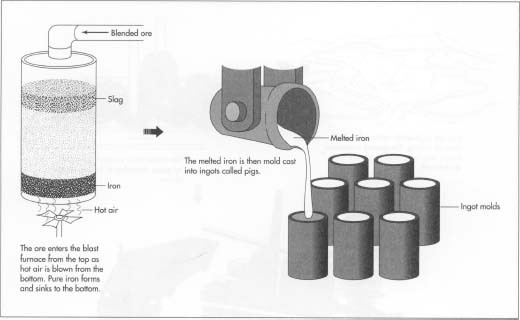

The product of the blast furnace is called pig iron and contains about 4 carbon and small amounts of manganese silicon phosphorus and sulfur. Smelting iron from iron ore using a bloomery furnace by members of the wealden iron research group the website for the wealden iron research group is http. An impure ore that forms iron after being refined. The iron is usually found in the form of magnetite fe 3 o 4 72 4 fe hematite fe 2 o 3 69 9 fe goethite feo oh 62 9 fe. The ores are usually rich in iron oxides and vary in color from dark grey bright yellow or deep purple to rusty red. In metallurgy refining consists of purifying an impure metal.

Source: intl.siyavula.com

Source: intl.siyavula.com

The iron is usually found in the form of magnetite fe 3 o 4 72 4 fe hematite fe 2 o 3 69 9 fe goethite feo oh 62 9 fe. Smelting iron from iron ore using a bloomery furnace by members of the wealden iron research group the website for the wealden iron research group is http. The iron is usually found in the form of magnetite fe 3 o 4 72 4 fe hematite fe 2 o 3 69 9 fe goethite feo oh 62 9 fe. To create pure iron one must deoxygenate the ore leaving only iron atoms behind which is the essence of the refining process. Refining 2 the mined ore is crushed and sorted.

In its natural form iron ore has a reddish hue and is mixed with various silicates. The best grades of ore contain over 60 iron. Item script dropped by. About to refine lots of iron ore. In this stage impurities such as sulfur phosphorus and excess carbon are removed from the raw iron and alloying elements such as manganese nickel chromium and vanadium are added to produce the exact steel required.

Source: brighthubengineering.com

Source: brighthubengineering.com

It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material whereas in refining the final material is usually identical chemically to the original one only it is purer. Item script dropped by. Each attempt to refine material consumes 1 mini furnace. The product of the blast furnace is called pig iron and contains about 4 carbon and small amounts of manganese silicon phosphorus and sulfur. Waste stove old stove 10 metaling 10 tao gunka 10 heavy metaling 10 skeleton worker 8 iron fist 7 5 deniro 4 5 deniro 4 5 piere 4 piere 4 andre 3 5 andre 3 5 pupa 3 stainer 3 thief bug female 3 steel chonchon 3 zerom.

Source: wisegeek.com

Source: wisegeek.com

Blacksmiths can refine iron ore into iron iron and coal into steel and elemental ores into elemental stones. However their is a by product from the process of refining that makes it so profitable extractions. Smelting iron from iron ore using a bloomery furnace by members of the wealden iron research group the website for the wealden iron research group is http. Lesser grades are treated or refined to remove various contaminants before the ore is shipped to the blast furnace. Waste stove old stove 10 metaling 10 tao gunka 10 heavy metaling 10 skeleton worker 8 iron fist 7 5 deniro 4 5 deniro 4 5 piere 4 piere 4 andre 3 5 andre 3 5 pupa 3 stainer 3 thief bug female 3 steel chonchon 3 zerom.

Source: practicalmaintenance.net

Source: practicalmaintenance.net

The product of the blast furnace is called pig iron and contains about 4 carbon and small amounts of manganese silicon phosphorus and sulfur. Iron ores are refined in the blast furnace. To create pure iron one must deoxygenate the ore leaving only iron atoms behind which is the essence of the refining process. Item script dropped by. Waste stove old stove 10 metaling 10 tao gunka 10 heavy metaling 10 skeleton worker 8 iron fist 7 5 deniro 4 5 deniro 4 5 piere 4 piere 4 andre 3 5 andre 3 5 pupa 3 stainer 3 thief bug female 3 steel chonchon 3 zerom.

Source: engineersgallery.com

Source: engineersgallery.com

The product of the blast furnace is called pig iron and contains about 4 carbon and small amounts of manganese silicon phosphorus and sulfur. It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material whereas in refining the final material is usually identical chemically to the original one only it is purer. An impure ore that forms iron after being refined. For material requirements see iron tempering steel tempering and enchantedstone craft. Iron ores are rocks and minerals from which metallic iron can be economically extracted.

Source: onlinemathlearning.com

Source: onlinemathlearning.com

For material requirements see iron tempering steel tempering and enchantedstone craft. Iron ores are refined in the blast furnace. Waste stove old stove 10 metaling 10 tao gunka 10 heavy metaling 10 skeleton worker 8 iron fist 7 5 deniro 4 5 deniro 4 5 piere 4 piere 4 andre 3 5 andre 3 5 pupa 3 stainer 3 thief bug female 3 steel chonchon 3 zerom. Smelting iron from iron ore using a bloomery furnace by members of the wealden iron research group the website for the wealden iron research group is http. For material requirements see iron tempering steel tempering and enchantedstone craft.

Blacksmiths can refine iron ore into iron iron and coal into steel and elemental ores into elemental stones. The product of the blast furnace is called pig iron and contains about 4 carbon and small amounts of manganese silicon phosphorus and sulfur. An impure ore that forms iron after being refined. To create pure iron one must deoxygenate the ore leaving only iron atoms behind which is the essence of the refining process. Iron ores are rocks and minerals from which metallic iron can be economically extracted.

Source: brighthubengineering.com

Source: brighthubengineering.com

Refining is the process of turning raw materials into processed materials for instance refining iron ores into iron ingots. In this stage impurities such as sulfur phosphorus and excess carbon are removed from the raw iron and alloying elements such as manganese nickel chromium and vanadium are added to produce the exact steel required. It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material whereas in refining the final material is usually identical chemically to the original one only it is purer. About to refine lots of iron ore. Waste stove old stove 10 metaling 10 tao gunka 10 heavy metaling 10 skeleton worker 8 iron fist 7 5 deniro 4 5 deniro 4 5 piere 4 piere 4 andre 3 5 andre 3 5 pupa 3 stainer 3 thief bug female 3 steel chonchon 3 zerom.

Source: ekomuseum.se

Source: ekomuseum.se

In this stage impurities such as sulfur phosphorus and excess carbon are removed from the raw iron and alloying elements such as manganese nickel chromium and vanadium are added to produce the exact steel required. Item script dropped by. About to refine lots of iron ore. Refining 2 the mined ore is crushed and sorted. Blacksmiths can refine iron ore into iron iron and coal into steel and elemental ores into elemental stones.

Source: madehow.com

Source: madehow.com

Smelting iron from iron ore using a bloomery furnace by members of the wealden iron research group the website for the wealden iron research group is http. However their is a by product from the process of refining that makes it so profitable extractions. Blacksmiths can refine iron ore into iron iron and coal into steel and elemental ores into elemental stones. Item script dropped by. Steelmaking is the second step in producing steel from iron ore.

Source: wisegeek.com

Source: wisegeek.com

Iron ores are rocks and minerals from which metallic iron can be economically extracted. Waste stove old stove 10 metaling 10 tao gunka 10 heavy metaling 10 skeleton worker 8 iron fist 7 5 deniro 4 5 deniro 4 5 piere 4 piere 4 andre 3 5 andre 3 5 pupa 3 stainer 3 thief bug female 3 steel chonchon 3 zerom. Iron ores are rocks and minerals from which metallic iron can be economically extracted. In this stage impurities such as sulfur phosphorus and excess carbon are removed from the raw iron and alloying elements such as manganese nickel chromium and vanadium are added to produce the exact steel required. Steelmaking is the second step in producing steel from iron ore.

Source: britannica.com

Source: britannica.com

Steelmaking is the second step in producing steel from iron ore. Item script dropped by. However their is a by product from the process of refining that makes it so profitable extractions. Lesser grades are treated or refined to remove various contaminants before the ore is shipped to the blast furnace. Blacksmiths can refine iron ore into iron iron and coal into steel and elemental ores into elemental stones.

Source: madehow.com

Source: madehow.com

Smelting iron from iron ore using a bloomery furnace by members of the wealden iron research group the website for the wealden iron research group is http. It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material whereas in refining the final material is usually identical chemically to the original one only it is purer. Iron ore consists of oxygen and iron atoms bonded together into molecules. Lesser grades are treated or refined to remove various contaminants before the ore is shipped to the blast furnace. In metallurgy refining consists of purifying an impure metal.

Source: chemguide.co.uk

Source: chemguide.co.uk

Iron ore being unloaded at docks in toledo ohio. Smelting iron from iron ore using a bloomery furnace by members of the wealden iron research group the website for the wealden iron research group is http. However their is a by product from the process of refining that makes it so profitable extractions. Lesser grades are treated or refined to remove various contaminants before the ore is shipped to the blast furnace. An impure ore that forms iron after being refined.

If you find this site adventageous, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title refining iron ore by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.