Qualities of brass

Qualities Of Brass. Brass is a part of our non ferrous metal processing. Hospital acquired pathogens such as mrsa cannot survive on brass doorknobs and fingerplates for more than a few hours. Copper gives brass its high malleability. Brass offers low friction and has low melting point of about 900 940 o c.

Choose The Best Brass Part To Suit Your Purpose By Pallega Issuu From issuu.com

Choose The Best Brass Part To Suit Your Purpose By Pallega Issuu From issuu.com

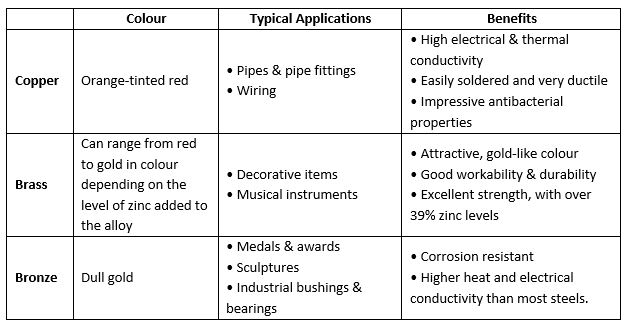

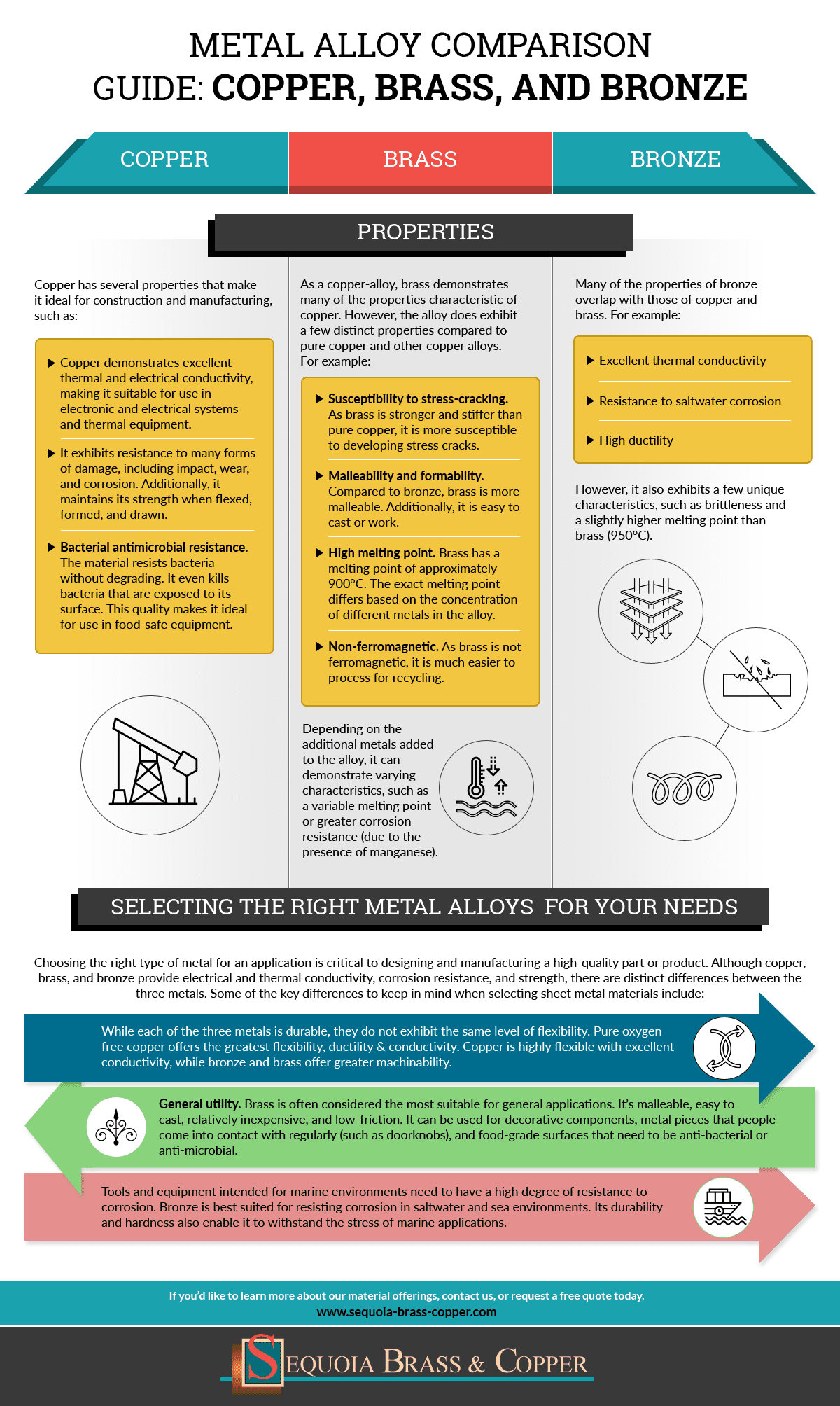

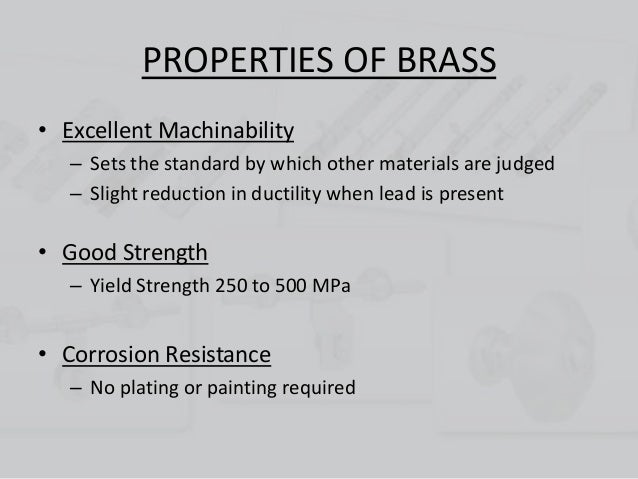

Brass doesn t possess magnetic properties hence is non ferromagnetic. A higher percentage of copper yields a rosy tone while more zinc makes the alloy appear silver. C difficile does not survive long on a brass or copper surface nor does e coli unlike stainless steel or plastic. Brass has higher malleability than either bronze or zinc. With these qualities alone it wouldn t make sense to keep asking what s brass worth because of the softness and malleability of brass it s very easy to cut and machine after being extruded eliminating the need for a cutting fluid which not only adds to the cost of manufacture but also affects the metal s overall quality. Brass has desirable acoustic properties appropriate for use in musical instruments.

Copper gives brass its high malleability.

Of the non ferrous metals copper is one of the most widely recycled closely followed by zinc recycling. Copper gives brass its high malleability. Low weight high conductivity non magnetic and corrosion resistance. C464 naval brass excellent for hot forming and adapts well to hot forging and pressing. The relatively low melting point of brass 900 to 940 c 1 650 to 1 720 f depending on composition and its flow characteristics make it a relatively easy material to cast. Brass has higher malleability than bronze or zinc.

Source: thoughtco.com

Source: thoughtco.com

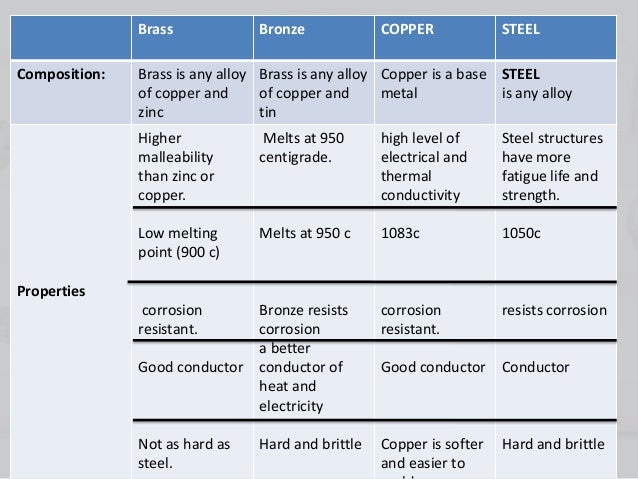

By varying the proportions of copper and zinc the properties of the brass can be changed allowing hard and soft brasses. Hospital acquired pathogens such as mrsa cannot survive on brass doorknobs and fingerplates for more than a few hours. Of the non ferrous metals copper is one of the most widely recycled closely followed by zinc recycling. Brass is a part of our non ferrous metal processing. C360 free cutting brass most common brass excellent high speed machining operations and superior thread rolling and knurling characteristics.

Source: thoughtco.com

Source: thoughtco.com

By varying the proportions of copper and zinc the properties of the brass can be changed allowing hard and soft brasses. Due to brass s unique composition it holds many properties. Most of the varieties of brass are recyclable. Hospital acquired pathogens such as mrsa cannot survive on brass doorknobs and fingerplates for more than a few hours. C360 free cutting brass most common brass excellent high speed machining operations and superior thread rolling and knurling characteristics.

Source: dorsetware.com

Source: dorsetware.com

The relatively low melting point of brass 900 to 940 c 1 650 to 1 720 f depending on composition and its flow characteristics make it a relatively easy material to cast. Brass has higher malleability than bronze or zinc. With these qualities alone it wouldn t make sense to keep asking what s brass worth because of the softness and malleability of brass it s very easy to cut and machine after being extruded eliminating the need for a cutting fluid which not only adds to the cost of manufacture but also affects the metal s overall quality. Here are some of the most useful ones. Brass often has a bright gold appearance however it can also be reddish gold or silvery white.

Source: sequoia-brass-copper.com

Source: sequoia-brass-copper.com

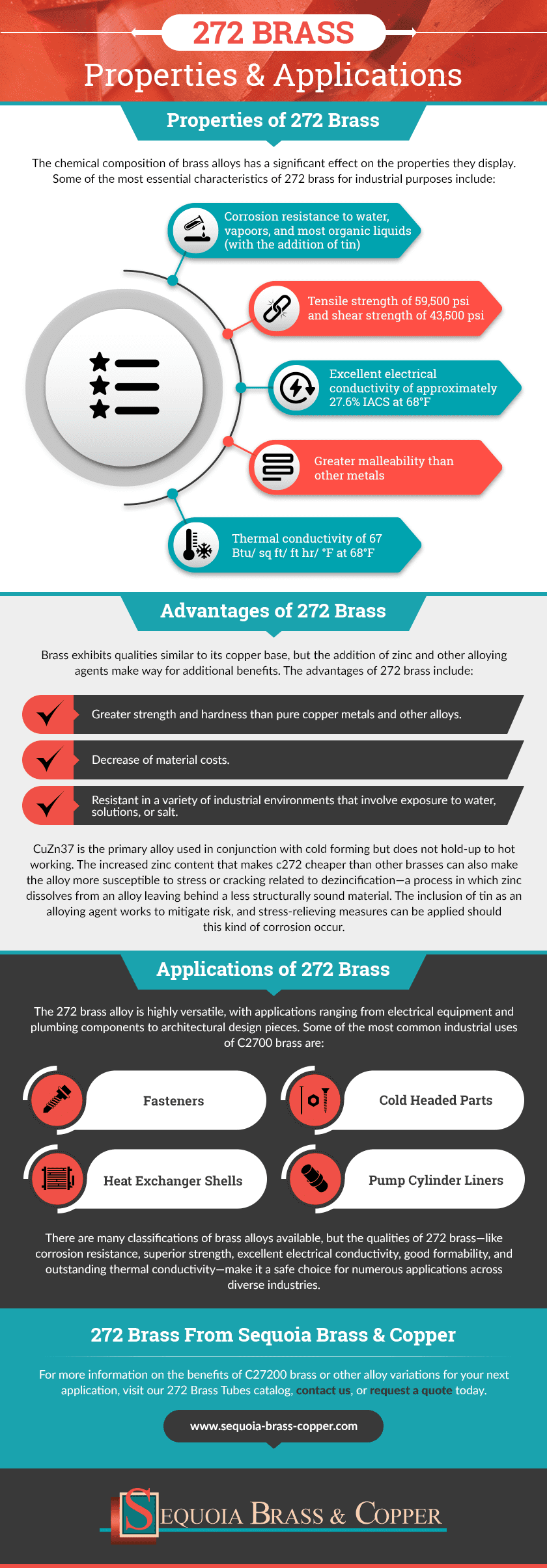

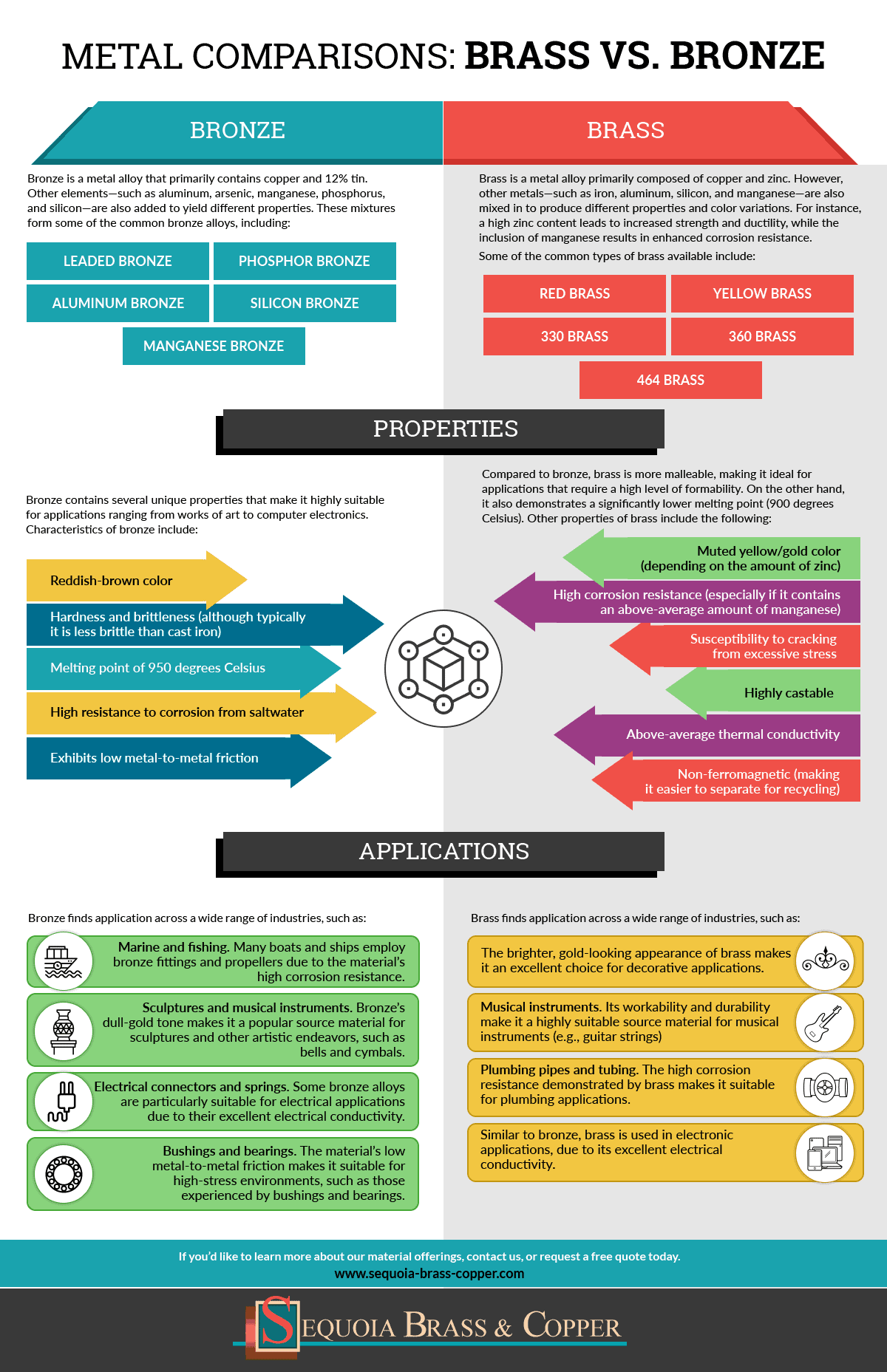

Non ferrous metals have quite extensive uses as their properties tend to be quite desirable. Brass has desirable acoustic properties appropriate for use in musical instruments. C360 free cutting brass most common brass excellent high speed machining operations and superior thread rolling and knurling characteristics. Low weight high conductivity non magnetic and corrosion resistance. Artists and architects value the metal s aesthetic properties as it can be produced in a range of colors from deep red to golden yellow.

Source: slideshare.net

Source: slideshare.net

Brass is a part of our non ferrous metal processing. By varying the proportions of copper and zinc the properties of the brass can be changed allowing hard and soft brasses. Brass has anti corrosive abilities that make it useful for naval hardware applications and its antimicrobial characteristics are valued in hospital settings where the spread of infection is a concern. Brass has higher malleability than either bronze or zinc. A great deal of experimenting is going on for use in hospitals.

Source: sequoia-brass-copper.com

Source: sequoia-brass-copper.com

Non ferrous metals have quite extensive uses as their properties tend to be quite desirable. Due to brass s unique composition it holds many properties. Here are some of the most useful ones. A higher percentage of copper yields a rosy tone while more zinc makes the alloy appear silver. Hospital acquired pathogens such as mrsa cannot survive on brass doorknobs and fingerplates for more than a few hours.

Source: issuu.com

Source: issuu.com

Brass has antibacterial and anti fouling qualities because mainly of its copper content brass is an effective antibacterial surface. Brass often has a bright gold appearance however it can also be reddish gold or silvery white. Artists and architects value the metal s aesthetic properties as it can be produced in a range of colors from deep red to golden yellow. Low weight high conductivity non magnetic and corrosion resistance. Brass is a part of our non ferrous metal processing.

Source: pinterest.com

Source: pinterest.com

Easily soldered and brazed and has very good resistance to corrosion. C difficile does not survive long on a brass or copper surface nor does e coli unlike stainless steel or plastic. C360 free cutting brass most common brass excellent high speed machining operations and superior thread rolling and knurling characteristics. Brass doesn t possess magnetic properties hence is non ferromagnetic. Due to brass s unique composition it holds many properties.

Source: thoughtco.com

Source: thoughtco.com

Of the non ferrous metals copper is one of the most widely recycled closely followed by zinc recycling. A higher percentage of copper yields a rosy tone while more zinc makes the alloy appear silver. By varying the proportions of copper and zinc the properties of the brass can be changed allowing hard and soft brasses. Brass offers low friction and has low melting point of about 900 940 o c. Brass has desirable acoustic properties appropriate for use in musical instruments.

Source: rotaxmetals.net

Source: rotaxmetals.net

Here are some of the most useful ones. Hospital acquired pathogens such as mrsa cannot survive on brass doorknobs and fingerplates for more than a few hours. Most of the varieties of brass are recyclable. Although bronze has copper too it isn t as malleable as brass due primarily to the difference in their added content. Easily soldered and brazed and has very good resistance to corrosion.

Source: azom.com

Source: azom.com

Brass is a part of our non ferrous metal processing. Brass has higher malleability than bronze or zinc. Brass is considered a low friction and non magnetic alloy while its acoustic properties have resulted in its use in many brass band musical instruments. Hospital acquired pathogens such as mrsa cannot survive on brass doorknobs and fingerplates for more than a few hours. Due to brass s unique composition it holds many properties.

Source: thoughtco.com

Source: thoughtco.com

C464 naval brass excellent for hot forming and adapts well to hot forging and pressing. C464 naval brass excellent for hot forming and adapts well to hot forging and pressing. Here are some of the most useful ones. C360 free cutting brass most common brass excellent high speed machining operations and superior thread rolling and knurling characteristics. A higher percentage of copper yields a rosy tone while more zinc makes the alloy appear silver.

Source: sequoia-brass-copper.com

Source: sequoia-brass-copper.com

Low weight high conductivity non magnetic and corrosion resistance. C464 naval brass excellent for hot forming and adapts well to hot forging and pressing. Brass offers low friction and has low melting point of about 900 940 o c. Due to brass s unique composition it holds many properties. Easily soldered and brazed and has very good resistance to corrosion.

Source: sciencestruck.com

Source: sciencestruck.com

Although bronze has copper too it isn t as malleable as brass due primarily to the difference in their added content. Hospital acquired pathogens such as mrsa cannot survive on brass doorknobs and fingerplates for more than a few hours. Copper gives brass its high malleability. Brass is considered a low friction and non magnetic alloy while its acoustic properties have resulted in its use in many brass band musical instruments. With these qualities alone it wouldn t make sense to keep asking what s brass worth because of the softness and malleability of brass it s very easy to cut and machine after being extruded eliminating the need for a cutting fluid which not only adds to the cost of manufacture but also affects the metal s overall quality.

Source: slideshare.net

Source: slideshare.net

A great deal of experimenting is going on for use in hospitals. Brass often has a bright gold appearance however it can also be reddish gold or silvery white. Brass has higher malleability than either bronze or zinc. Brass doesn t possess magnetic properties hence is non ferromagnetic. Brass has higher malleability than bronze or zinc.

If you find this site convienient, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title qualities of brass by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.