Gold plating electrolyte

Gold Plating Electrolyte. The gold plating electrolyte according to the present invention as compared to that of the prior art has an increased content of hexapotassium m ethylenediaminetetraacetatobis aurous sulphite and the process for producing it makes it possible to simplify the technology and substantially fully avoid irrevocable mechanical losses of gold. Gold electroplating is a method of depositing a thin layer of gold onto the surface of another metal. Gold plating finds its uses in jewelry semiconductor industry. More than 12 months start point of the electrolyte decomposition d k 15 a dm 2.

Pdf Non Cyanide Electrolytes For Gold Plating A Review Semantic Scholar From semanticscholar.org

Pdf Non Cyanide Electrolytes For Gold Plating A Review Semantic Scholar From semanticscholar.org

Gold plating will look uneven and smudged if the surface is dirty oily scratched or otherwise damaged. It often employed in electronics to provide a corrosion resistant surface. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility. Deposits are up to 200 μm. Gold plating finds its uses in jewelry semiconductor industry. We also connect the substrate the material that we ll be plating to the cathode which is the negatively charged electrode.

It often employed in electronics to provide a corrosion resistant surface.

Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility. More than 12 months start point of the electrolyte decomposition d k 15 a dm 2. Auruna 553 neutral fine gold electrolyte produces silk matte coatings of exceptional ductility. Hardness is approximately 90 hv 0 01. It also provides adhesive activation of the basic material and protection of the main gold bath from contamination. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility.

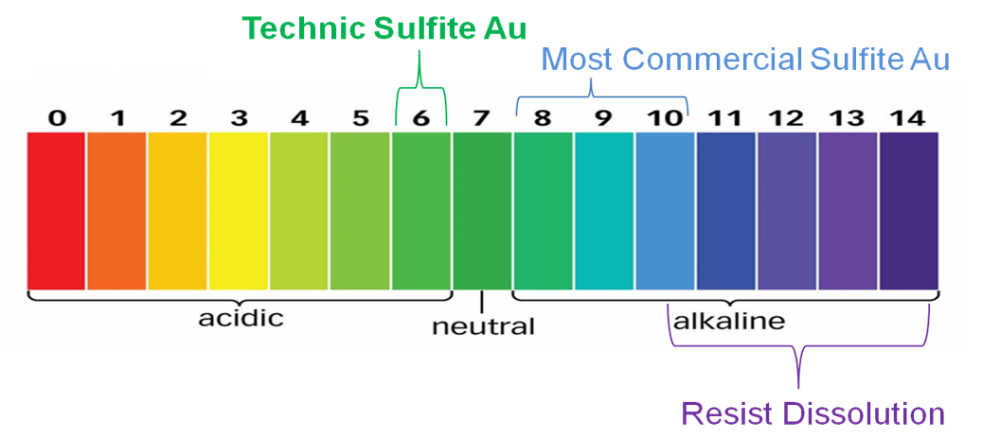

Source: technic.com

Source: technic.com

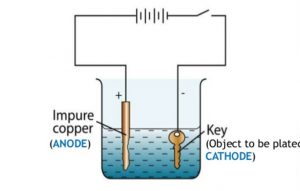

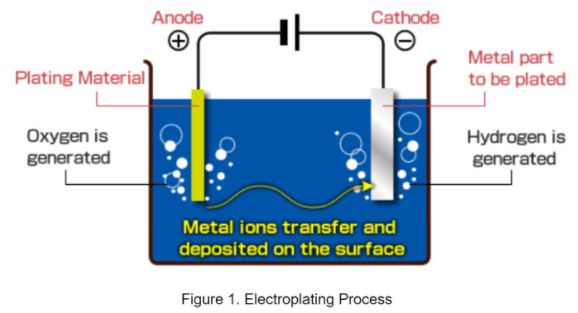

We also connect the substrate the material that we ll be plating to the cathode which is the negatively charged electrode. The gold plating electrolyte according to the present invention possesses a throwing power of up to 80 yield current of 80 90 time of storage at the temperature of 25 c. More than 12 months start point of the electrolyte decomposition d k 15 a dm 2. Hardness is approximately 90 hv 0 01. Gold electroplating is a method of depositing a thin layer of gold onto the surface of another metal.

Source: classnotes.org.in

Source: classnotes.org.in

Hardness is approximately 90 hv 0 01. More than 12 months start point of the electrolyte decomposition d k 15 a dm 2. Deposits are up to 200 μm. We also connect the substrate the material that we ll be plating to the cathode which is the negatively charged electrode. Gold electroplating is a method of depositing a thin layer of gold onto the surface of another metal.

Source: explainthatstuff.com

Source: explainthatstuff.com

Auruna 553 neutral fine gold electrolyte produces silk matte coatings of exceptional ductility. More than 12 months start point of the electrolyte decomposition d k 15 a dm 2. Gold plating will look uneven and smudged if the surface is dirty oily scratched or otherwise damaged. Auruna 551 mildly acidic electrolyte deposits thin pure gold 0 05 0 1 μm as gold strike layers for neutral or alkaline gold plating baths. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility.

Source: researchgate.net

Source: researchgate.net

To plate an item with electro deposition we connect the gold to the anode the positively charged electrode of an electrical circuit. Baths have been formulated using acidic neutral and basic solutions to which agents are added to tie up impurities and to brighten harden and control the metal grain size. It often employed in electronics to provide a corrosion resistant surface. In all gold plating the part is polished and cleaned as thoroughly as possible before the electroplating process starts. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility.

Source: semanticscholar.org

Source: semanticscholar.org

Gold plating finds its uses in jewelry semiconductor industry. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility. Auruna 551 mildly acidic electrolyte deposits thin pure gold 0 05 0 1 μm as gold strike layers for neutral or alkaline gold plating baths. Gold plating will look uneven and smudged if the surface is dirty oily scratched or otherwise damaged. The gold plating electrolyte according to the present invention as compared to that of the prior art has an increased content of hexapotassium m ethylenediaminetetraacetatobis aurous sulphite and the process for producing it makes it possible to simplify the technology and substantially fully avoid irrevocable mechanical losses of gold.

Source: sciencedirect.com

Source: sciencedirect.com

Auruna 553 neutral fine gold electrolyte produces silk matte coatings of exceptional ductility. Hardness is approximately 90 hv 0 01. To plate an item with electro deposition we connect the gold to the anode the positively charged electrode of an electrical circuit. Modern electroplating begins with the creation of a metal salt using the plating metal typically gold or silver. Gold plating will look uneven and smudged if the surface is dirty oily scratched or otherwise damaged.

Source: slideplayer.com

Source: slideplayer.com

Currently electrolytic gold plating is done using au cn 2 or to a lesser extent au so 3 3 3 usually as the potassium salt. It also provides adhesive activation of the basic material and protection of the main gold bath from contamination. Baths have been formulated using acidic neutral and basic solutions to which agents are added to tie up impurities and to brighten harden and control the metal grain size. The gold plating electrolyte according to the present invention as compared to that of the prior art has an increased content of hexapotassium m ethylenediaminetetraacetatobis aurous sulphite and the process for producing it makes it possible to simplify the technology and substantially fully avoid irrevocable mechanical losses of gold. Gold plating will look uneven and smudged if the surface is dirty oily scratched or otherwise damaged.

Source: qualityinspection.org

Source: qualityinspection.org

The gold plating electrolyte according to the present invention possesses a throwing power of up to 80 yield current of 80 90 time of storage at the temperature of 25 c. We also connect the substrate the material that we ll be plating to the cathode which is the negatively charged electrode. In all gold plating the part is polished and cleaned as thoroughly as possible before the electroplating process starts. The gold plating electrolyte according to the present invention as compared to that of the prior art has an increased content of hexapotassium m ethylenediaminetetraacetatobis aurous sulphite and the process for producing it makes it possible to simplify the technology and substantially fully avoid irrevocable mechanical losses of gold. Deposits are up to 200 μm.

Source: wikiwand.com

Source: wikiwand.com

Auruna 553 neutral fine gold electrolyte produces silk matte coatings of exceptional ductility. The gold plating electrolyte according to the present invention possesses a throwing power of up to 80 yield current of 80 90 time of storage at the temperature of 25 c. In this instructable i am making alkaline gold plating solution which can deposit gold by electrolysis. Auruna 551 mildly acidic electrolyte deposits thin pure gold 0 05 0 1 μm as gold strike layers for neutral or alkaline gold plating baths. Gold electroplating is a method of depositing a thin layer of gold onto the surface of another metal.

Source: researchgate.net

Source: researchgate.net

Deposits are up to 200 μm. Hardness is approximately 90 hv 0 01. The gold plating electrolyte according to the present invention as compared to that of the prior art has an increased content of hexapotassium m ethylenediaminetetraacetatobis aurous sulphite and the process for producing it makes it possible to simplify the technology and substantially fully avoid irrevocable mechanical losses of gold. It also provides adhesive activation of the basic material and protection of the main gold bath from contamination. Deposits are up to 200 μm.

Source: watchplating.com

Source: watchplating.com

Hardness is approximately 90 hv 0 01. Baths have been formulated using acidic neutral and basic solutions to which agents are added to tie up impurities and to brighten harden and control the metal grain size. Auruna 553 neutral fine gold electrolyte produces silk matte coatings of exceptional ductility. We then immerse both pieces in an electrolytic solution. Auruna 551 mildly acidic electrolyte deposits thin pure gold 0 05 0 1 μm as gold strike layers for neutral or alkaline gold plating baths.

Source:

We also connect the substrate the material that we ll be plating to the cathode which is the negatively charged electrode. To plate an item with electro deposition we connect the gold to the anode the positively charged electrode of an electrical circuit. Deposits are up to 200 μm. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility. The gold plating electrolyte according to the present invention as compared to that of the prior art has an increased content of hexapotassium m ethylenediaminetetraacetatobis aurous sulphite and the process for producing it makes it possible to simplify the technology and substantially fully avoid irrevocable mechanical losses of gold.

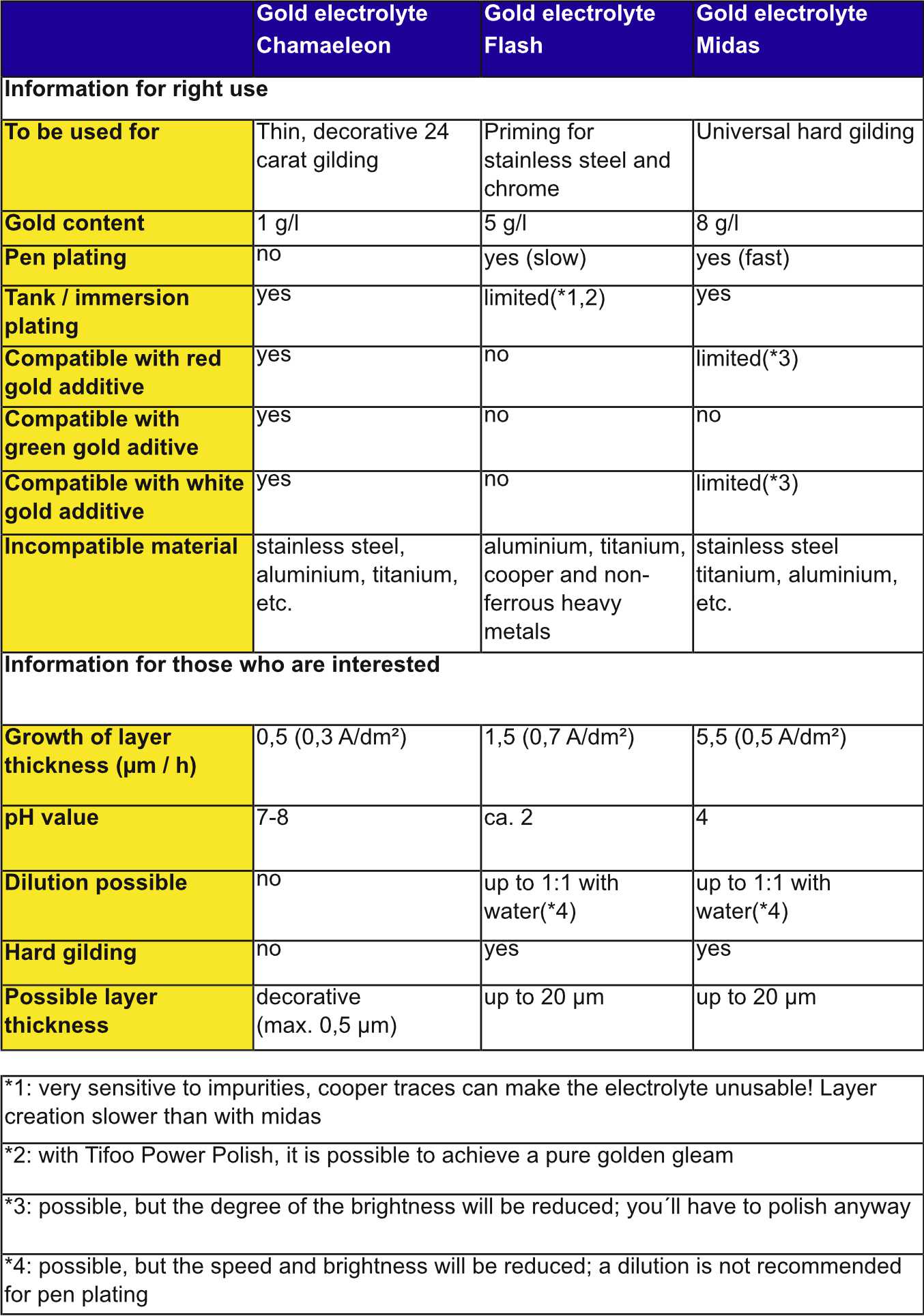

Source: tifoo-plating.com

Source: tifoo-plating.com

Baths have been formulated using acidic neutral and basic solutions to which agents are added to tie up impurities and to brighten harden and control the metal grain size. In this instructable i am making alkaline gold plating solution which can deposit gold by electrolysis. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility. Gold plating will look uneven and smudged if the surface is dirty oily scratched or otherwise damaged. Auruna 553 neutral fine gold electrolyte produces silk matte coatings of exceptional ductility.

Source: docbrown.info

Source: docbrown.info

Gold plating will look uneven and smudged if the surface is dirty oily scratched or otherwise damaged. Modern electroplating begins with the creation of a metal salt using the plating metal typically gold or silver. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility. Gold electroplating is a method of depositing a thin layer of gold onto the surface of another metal. Auruna 553 neutral fine gold electrolyte produces silk matte coatings of exceptional ductility.

Source: ganoksin.com

Source: ganoksin.com

Currently electrolytic gold plating is done using au cn 2 or to a lesser extent au so 3 3 3 usually as the potassium salt. We also connect the substrate the material that we ll be plating to the cathode which is the negatively charged electrode. Baths have been formulated using acidic neutral and basic solutions to which agents are added to tie up impurities and to brighten harden and control the metal grain size. Advanced plating technologies offers gold plating in both 99 7 pure hard gold and 99 9 pure soft gold electrodeposits hard gold plating services are commonly used for applications where repeated sliding or connection wear is a design consideration soft gold plating is commonly used where the highest of gold purity is required for soldering wire bonding high temperature biocompatibility. Gold plating will look uneven and smudged if the surface is dirty oily scratched or otherwise damaged.

If you find this site serviceableness, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title gold plating electrolyte by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.