Copper plating process

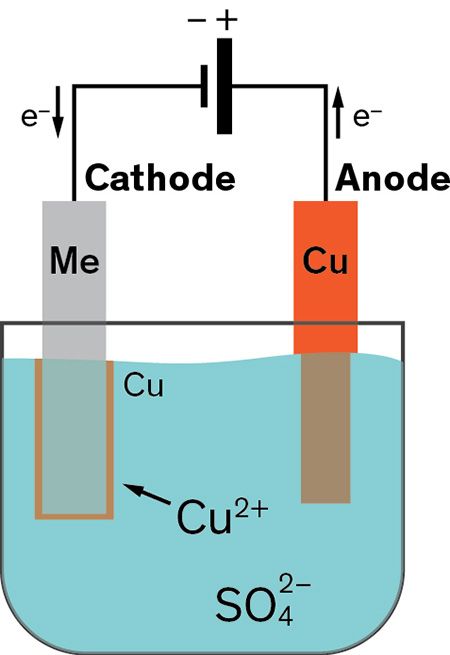

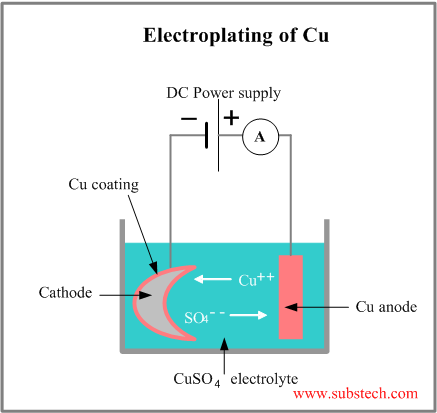

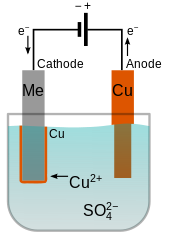

Copper Plating Process. From wikipedia the free encyclopedia electroless copper plating is a chemical process that deposits an even layer of copper on the surface of a solid substrate like metal or plastic. In this role copper provides adhesion and or increases corrosion resistance as well as thermal and electrical conductivity of. Submerge the wafer to be plated into an electrolyte bath apply a current and copper ions will migrate and deposit onto regions with a pre existing metal seed layer. Copper goes into solution at the anode as it is plated at the cathode.

What Is The Chemical Equation For Copper Electroplating Using The Solution Of Cuso4 Quora From quora.com

What Is The Chemical Equation For Copper Electroplating Using The Solution Of Cuso4 Quora From quora.com

Generally palladium particles are used palladium is a very expensive metal with high price and rising all the time. There are many essential steps in the copper electroplating process to ensure a highly functional finished product. A standard electrolyte has the following composition. Copper electroplating can be done on plastic and other non metallic surfaces essentially metalizing plastic parts. Take a fourth of the copper scoring pad half of what is left of the one you pulled apart and create a teardrop shape. From wikipedia the free encyclopedia electroless copper plating is a chemical process that deposits an even layer of copper on the surface of a solid substrate like metal or plastic.

In this role copper provides adhesion and or increases corrosion resistance as well as thermal and electrical conductivity of.

Plating processes for many applications are known with varying results for the characteristic properties of the deposits. Take a fourth of the copper scoring pad half of what is left of the one you pulled apart and create a teardrop shape. Copper plating is the main deposition process for the production of printed circuit boards. From wikipedia the free encyclopedia electroless copper plating is a chemical process that deposits an even layer of copper on the surface of a solid substrate like metal or plastic. Electroless plating is widely used in the printed circuit board pcb production and processing which has holes on that and it can also be called pth plate through hole the main purpose is to deposit a layer of copper through a series of chemical treatment methods in the conductive substrate and then increasing the thickness of. Copper electroplating on plastic.

Source: quora.com

Source: quora.com

Plating processes for many applications are known with varying results for the characteristic properties of the deposits. Take a fourth of the copper scoring pad half of what is left of the one you pulled apart and create a teardrop shape. Copper electroplating on plastic. From wikipedia the free encyclopedia electroless copper plating is a chemical process that deposits an even layer of copper on the surface of a solid substrate like metal or plastic. The electroplating process creates bubbles which can get trapped in your wire mesh.

Source: sdy-pcb.com

Source: sdy-pcb.com

Electroless plating copper also known as copper deposition or pore forming pth is a self catalytic redox reaction. Take a fourth of the copper scoring pad half of what is left of the one you pulled apart and create a teardrop shape. Electroless plating copper also known as copper deposition or pore forming pth is a self catalytic redox reaction. Galvanised copper coating combines protection functionality and aesthetics. The electroplating process creates bubbles which can get trapped in your wire mesh.

Technical analysis of plating copper for pcb processing. Copper electroplating bath the concept of copper electroplating is straightforward. The process involves dipping the substrate in a water solution containing copper salts and a reducing agent such as formaldehyde. Copper goes into solution at the anode as it is plated at the cathode. Into a container of water are placed a copper rod and the item.

Source: raypcb.com

Source: raypcb.com

It takes place in an electrolytic cell where electrolysis which uses direct electric current to dissolve a copper rod and transport the copper ions to the item. It takes place in an electrolytic cell where electrolysis which uses direct electric current to dissolve a copper rod and transport the copper ions to the item. Copper electroplating bath the concept of copper electroplating is straightforward. From wikipedia the free encyclopedia electroless copper plating is a chemical process that deposits an even layer of copper on the surface of a solid substrate like metal or plastic. Technical analysis of plating copper for pcb processing.

Source: microminus.com

Source: microminus.com

Electroless plating is widely used in the printed circuit board pcb production and processing which has holes on that and it can also be called pth plate through hole the main purpose is to deposit a layer of copper through a series of chemical treatment methods in the conductive substrate and then increasing the thickness of. Copper electroplating bath the concept of copper electroplating is straightforward. You want the fatter end to be very tightly packed so that it doesn t float. Copper electroplating can be done on plastic and other non metallic surfaces essentially metalizing plastic parts. Copper is an excellent conductor of electricity and heat and is often used as the first building block for many coating systems.

Source: pcbway.com

Source: pcbway.com

Electroless plating is widely used in the printed circuit board pcb production and processing which has holes on that and it can also be called pth plate through hole the main purpose is to deposit a layer of copper through a series of chemical treatment methods in the conductive substrate and then increasing the thickness of. Copper electroplating can be done on plastic and other non metallic surfaces essentially metalizing plastic parts. Firstly an activator is used to adsorb a layer of active particles on the surface of the insulating substrate. It takes place in an electrolytic cell where electrolysis which uses direct electric current to dissolve a copper rod and transport the copper ions to the item. Copper plating is the main deposition process for the production of printed circuit boards.

Source: docbrown.info

Source: docbrown.info

Electroless plating is widely used in the printed circuit board pcb production and processing which has holes on that and it can also be called pth plate through hole the main purpose is to deposit a layer of copper through a series of chemical treatment methods in the conductive substrate and then increasing the thickness of. Submerge the wafer to be plated into an electrolyte bath apply a current and copper ions will migrate and deposit onto regions with a pre existing metal seed layer. Copper electroplating on plastic. Plating processes for many applications are known with varying results for the characteristic properties of the deposits. Copper is an excellent conductor of electricity and heat and is often used as the first building block for many coating systems.

Source: shuobaocn.com

Source: shuobaocn.com

The process involves dipping the substrate in a water solution containing copper salts and a reducing agent such as formaldehyde. Copper is an excellent conductor of electricity and heat and is often used as the first building block for many coating systems. There are many essential steps in the copper electroplating process to ensure a highly functional finished product. Copper plating is the process of plating a layer of copper electrolytically on the surface of an item. Submerge the wafer to be plated into an electrolyte bath apply a current and copper ions will migrate and deposit onto regions with a pre existing metal seed layer.

Source: researchgate.net

Source: researchgate.net

Plating processes for many applications are known with varying results for the characteristic properties of the deposits. Copper goes into solution at the anode as it is plated at the cathode. Items to consider when placing an order for copper plating include coating requirements sampling and test proceduresand final rejection rehearing or certification. Into a container of water are placed a copper rod and the item. It takes place in an electrolytic cell where electrolysis which uses direct electric current to dissolve a copper rod and transport the copper ions to the item.

Source: highnicgroup.com

Source: highnicgroup.com

Firstly an activator is used to adsorb a layer of active particles on the surface of the insulating substrate. Take a fourth of the copper scoring pad half of what is left of the one you pulled apart and create a teardrop shape. A standard electrolyte has the following composition. Technical analysis of plating copper for pcb processing. Electroless plating copper also known as copper deposition or pore forming pth is a self catalytic redox reaction.

Source: researchgate.net

Source: researchgate.net

The electroplating process creates bubbles which can get trapped in your wire mesh. Take a fourth of the copper scoring pad half of what is left of the one you pulled apart and create a teardrop shape. A standard electrolyte has the following composition. The process involves dipping the substrate in a water solution containing copper salts and a reducing agent such as formaldehyde. Electroplating example a simple example of the electroplating process is the electroplating of copper in which the metal to be plated copper is used as the anode and the electrolyte solution contains the ion of the metal to be plated cu 2 in this example.

Source: explainthatstuff.com

Source: explainthatstuff.com

A standard electrolyte has the following composition. Copper plating is the main deposition process for the production of printed circuit boards. Generally palladium particles are used palladium is a very expensive metal with high price and rising all the time. A standard electrolyte has the following composition. Electroless plating is widely used in the printed circuit board pcb production and processing which has holes on that and it can also be called pth plate through hole the main purpose is to deposit a layer of copper through a series of chemical treatment methods in the conductive substrate and then increasing the thickness of.

Source: substech.com

Source: substech.com

The process involves dipping the substrate in a water solution containing copper salts and a reducing agent such as formaldehyde. It takes place in an electrolytic cell where electrolysis which uses direct electric current to dissolve a copper rod and transport the copper ions to the item. Plating processes for many applications are known with varying results for the characteristic properties of the deposits. The electroplating process creates bubbles which can get trapped in your wire mesh. In this role copper provides adhesion and or increases corrosion resistance as well as thermal and electrical conductivity of.

Source: raypcb.com

Source: raypcb.com

Copper goes into solution at the anode as it is plated at the cathode. The process involves dipping the substrate in a water solution containing copper salts and a reducing agent such as formaldehyde. In this role copper provides adhesion and or increases corrosion resistance as well as thermal and electrical conductivity of. Copper electroplating on plastic. Into a container of water are placed a copper rod and the item.

Source: en.wikipedia.org

Source: en.wikipedia.org

Copper is an excellent conductor of electricity and heat and is often used as the first building block for many coating systems. Copper electroplating on plastic. It takes place in an electrolytic cell where electrolysis which uses direct electric current to dissolve a copper rod and transport the copper ions to the item. You want the fatter end to be very tightly packed so that it doesn t float. Electroplating example a simple example of the electroplating process is the electroplating of copper in which the metal to be plated copper is used as the anode and the electrolyte solution contains the ion of the metal to be plated cu 2 in this example.

If you find this site adventageous, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title copper plating process by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.